Thermal expansion

Thermal expansion depends on surface temperature, thus on the colour of the surface treatment.

Maximum temperature increase of the outer surface is:

- Anodized natural surface: approx. 30°C.

- Thermolacquered ‘not white’ surface: up to 70°C.

Thermal expansion of aluminium elements used in facades is empirically admitted to be approx. +/-1.2 mm/metre for a temperature difference of 100°C. This order of magnitude is also valid for Profile Design System cladding.

In practice, following principle is agreed upon:

- Installation should take place at a temperature of 20°C.

- Expansion at a temperature of −10°C for profile length of 3m: −2 to −3 mm.

profile length of 6m.: −5 to −6 mm. - Expansion at a temperature of +70°C for profile length of 3m: +2 to +3 mm.

profile length of 6m.: +5 to +6 mm.

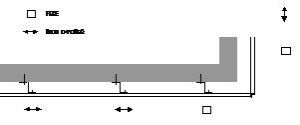

For profile lengths of 3 metres an expansion joint of 2 to 3 mm is thus required, for profile lengths of 6 metres, the expansion joint shall be 5 to 6 mm.

Recommendation for the installation of large elements:

- Fixed point to be located near the angles of the building; oval shaped holes for the other anchor points.

- Fixed point to be located in the centre of the profile; oval shaped holes for the other anchor points.